Key Takeaways

- Suspension casters enhance equipment mobility and ensure stability by reducing vibrations.

- Use the correct caster type based on load capacity and surface type.

- Regular maintenance is essential for long-lasting caster performance.

- The latest advancements in caster technology help meet modern industrial demands.

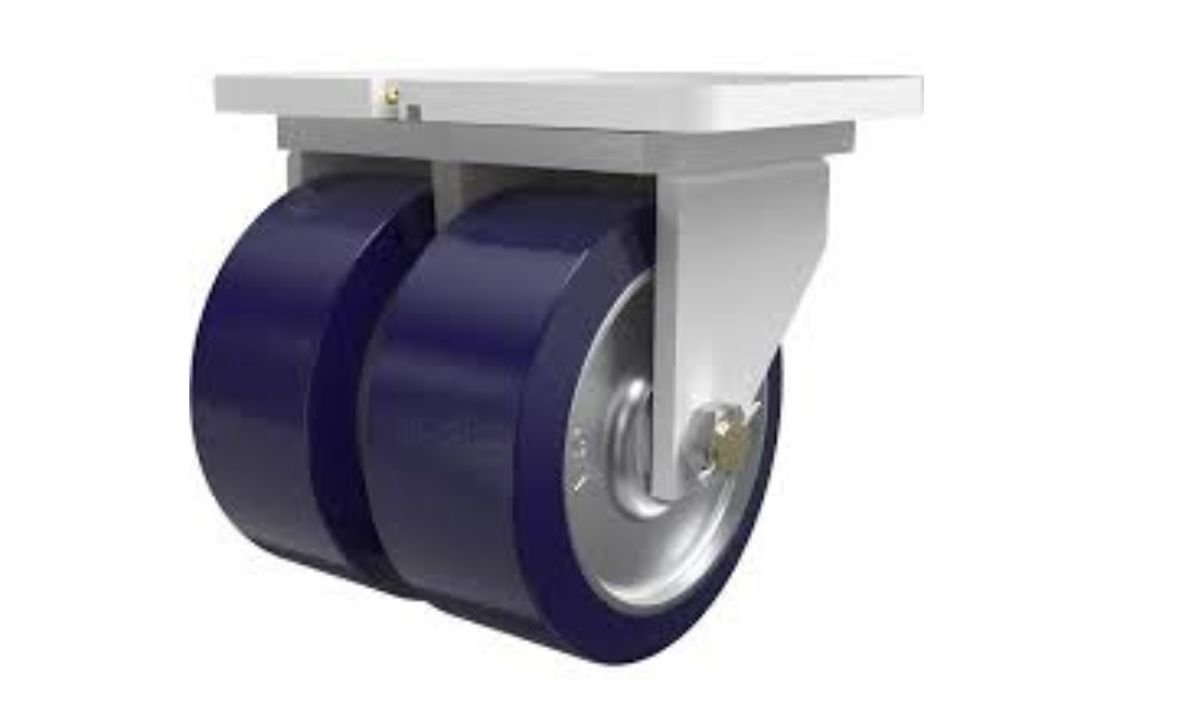

Understanding Suspension Casters

Suspension casters are pivotal in enhancing heavy equipment’s mobility and stability. Unlike standard wheels, they are engineered to absorb shocks and minimize vibrations, making them indispensable in industries where smooth, stable movement is critical. This includes manufacturing, healthcare, and even delicate environments such as laboratories. Incorporating suspension casters into your operations can drastically improve the efficiency with which equipment is maneuvered across various surfaces. From uneven factory floors to sensitive hospital corridors, these casters provide the consistency needed to prevent mechanical hiccups and ensure the safety of both equipment and personnel.

Types of Suspension Casters

Rigid Casters

- Rigid casters are known for their simplicity and rigidity, making them ideally suited for applications requiring stable, straightforward movement. These casters can support substantial weight without sacrificing durability, making them extremely useful in factories and warehouses. Despite their tendency to lack directional flexibility, the strength they offer makes them a valuable component in any heavy-duty operation, capable of facilitating efficient, straight-line transport over predictable pathways.

Swivel Casters

- In contrast, swivel casters are distinguished by their impressive maneuverability. These casters allow for multidirectional movement, particularly in environments like hospitals and retail stores where space is limited and dexterity is essential. The ability of swivel casters to pivot in place enables equipment to navigate crowded spaces seamlessly without the repetitive lifting or excessive directional adjustments required by more rigid systems.

Applications in Various Industries

The versatility of suspension casters allows them to be incorporated into various industrial applications. In the manufacturing sector, they make moving massive machinery and bulky components feasible with minimum physical strain and maximum efficiency. This capability accelerates the production process and minimizes potential damage to equipment by ensuring smooth transitions from one location to another. In healthcare, suspension casters contribute to sensitive medical equipment’s quiet, efficient movement, ensuring that devices reach their destination without undue disturbance. The casters’ ability to deliver reliable performance on various surfaces is a key asset in optimizing workflow efficiency across diverse operational contexts.

How to Choose the Right Caster for Your Needs

Selecting the appropriate caster involves analyzing several critical factors, including load capacity, wheel diameter, material composition, and environmental considerations. Choosing incorrectly can lead to equipment instability or premature wear and tear. For environments exposed to corrosive substances or extreme temperatures, selecting materials specially designed to withstand these conditions is essential. Consulting resources like supply chain insights can provide invaluable guidance, aligning your choices with industry best practices to ensure the selected casters meet specific operational needs.

Maintenance Tips for Long-lasting Performance

- Regular Inspection: It is imperative to conduct regular inspections to identify wear and tear before they evolve into substantial issues.

- Lubrication: Keeping moving parts lubricated cannot be overstated. Proper lubrication ensures smooth movement and reduces friction, and it can also extend the lifespan of the casters by preventing mechanical fatigue.

- Alignment: It is crucial to regularly verify that the casters remain aligned and securely attached to the equipment. Misalignment can lead to imbalanced weight distribution, increasing the risk of tipping or unnecessary strain on the caster elements.

Emerging Trends in Caster Technology

Innovation in caster technology continues to advance, driven by demands for improved efficiency, safety, and adaptability in modern operations. Recent developments include innovative materials offering enhanced shock absorption and improved durability. Moreover, some of the latest models come equipped with noise reduction and less maintenance-intensive designs, responding to the needs of industries that prioritize quiet and efficient operation. Keeping an eye on the latest industry innovations benefits businesses seeking to stay ahead by leveraging these new technologies to optimize their processes.

Caster Usage: Dos and Don’ts

- Do: Ensure that any chosen caster matches your equipment’s operational requirements and load demands. This reduces risks associated with inefficient load handling and enhances safety during operations.

- Don’t: Avoid overburdening casters beyond their rated capacity. Doing so can lead to disastrous outcomes, including equipment failure or workplace accidents.

Conclusion: The Impact of Suspension Casters on Equipment Performance

Integrating suspension casters into operational setups significantly enhances equipment mobility and stability, providing businesses with a versatile tool that ensures smoother, more reliable performance. Companies can maximize efficiency and safety in transport operations through proper selection, application, and maintenance. The ongoing improvements in caster technology ensure that enterprises can confidently meet new and emerging challenges, equipping them with the means to maintain a competitive advantage.